|

|

|

Home > Product > Built-in

Spindle |

|

|

|

|

|

|

|

|

|

| . Features |

|

1. Reduced

motor heat generation through loss reduction using mulit-polarization

method |

|

2. Main shaft servo-mechanization

through C-shaft control, main

shaft synchronization and

synchronized tap(Rigid Tap) using high resolution encoder for built-in milling motor control |

|

3. Expanded positive output

range and low-speed, high-torque using wide

area positive output,

dedicated controller and

coil transfer method |

|

4. Low-speed, high-torque

and high speed, high output using our electronic

power transfer method |

|

|

|

|

| Model |

KB-3 |

※ MITSUBISHI, FANUC,

SSD-Rotor, Stator,

Sensor, Drive |

KB-4 |

| Steel

brg + greased |

min¹ |

18,000 |

13,000 |

| Ceramic

brg + greased |

min¹ |

25,000 |

18,000 |

| Ceramic

brg + Oil-Air Lubrication |

min¹ |

30,000 |

24,000 |

| Power |

Kw |

10 |

10/8.5 |

| Voltage |

V |

380 |

380 |

| Pole |

P |

4 |

4 |

| Tooling

System |

|

BT30,

HSK40E |

BT40,

HSK50E |

| Weight |

Kg |

27 |

45 |

| Tool

change pressure |

bar |

30 |

35 |

| Torque |

Nm |

6.7N-m |

S1:15N-m S3:18N-m |

| Tool

release |

|

HY(Booster) |

HY(Booster) |

| Encoder |

Pulse |

Resolver |

Resolver |

|

| |

|

|

| Model |

KB-3-1 |

※ MITSUBISHI, FANUC,

SSD-Rotor, Stator,

Sensor, Drive |

KB-4-1 |

| Steel

brg + greased |

min¹ |

18,000 |

13,000 |

| Ceramic

brg + greased |

min¹ |

25,000 |

18,000 |

| Ceramic

brg + Oil-Air Lubrication |

min¹ |

30,000 |

24,000 |

| Power |

Kw |

7.5

/ 5.5 |

11 / 7.5 |

| Voltage |

V |

220 |

220 |

| Pole |

P |

4 |

4 |

| Tooling

System |

|

BT30,

HSK40E |

BT40,

HSK50E |

| Weight |

Kg |

70 |

110 |

| Tool

change pressure |

bar |

30 |

35 |

| Torque |

Nm |

9.5 |

Rate:14.3N-m

Rate 10Min:21N-m |

| Tool

release |

|

HY(Booster) |

HY(Booster) |

| Encoder |

Pulse |

Encoder |

Encoder |

|

|

|

|

|

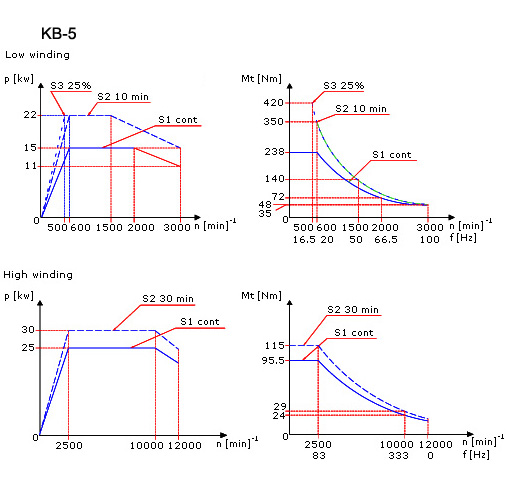

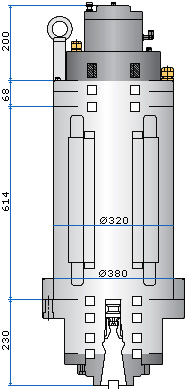

| KB-5 |

| BT

50 |

| max.

12,000 RPM |

|

|

● MOTOR-ENCODER:

● FANUC Code Nº A06B-1726-B100#Z311

(ALPHA B160LL/13000i)

● FANUC ENCODER Code Nº A860-2120-T401 |

|

|

|

|

|

|

|